Rolling shutter

Call Us: +91 7012411253

Components of a Rolling Shutter

Components of a rolling shutter are slat (lath), bottom section (bottom rail), channel section (guide channel), pipe shaft, side plates, springs, pulleys (ordinary/bearing), lock sets, and small fittings like handles, stoppers, sliding locks etc.

These components will be customized according to the operation, raw material used & position of fixing the rolling shutter (in the case of channel section and side plates). For example, for a gear operated rolling shutter a strong pipe shaft (a cage like design with MS flat) is used instead of normal ones and for motorized rolling shutters, a GI pipe shaft of 4 inches to 9 inches diameter will suit the best.

Types of Rolling Shutters

Based on Material

Galvanized (GI), cold-rolled (CR), perforated GI, powder Coated & mild steel (MS) – grill shutter.

Based on Thickness

We have a wide range of raw materials, each characterized by Gauges (thickness of the raw material) One can select the gauge of slats, starting from 18 gauge to 22 gauge. Lower the gauge value thicker the material used.

Based on Operation

Push & Pull Rolling shutters (manual), gear operated rolling shutters, motorized rolling shutters. Manual rolling shutters are widely used as they are inexpensive.

Based On Shape

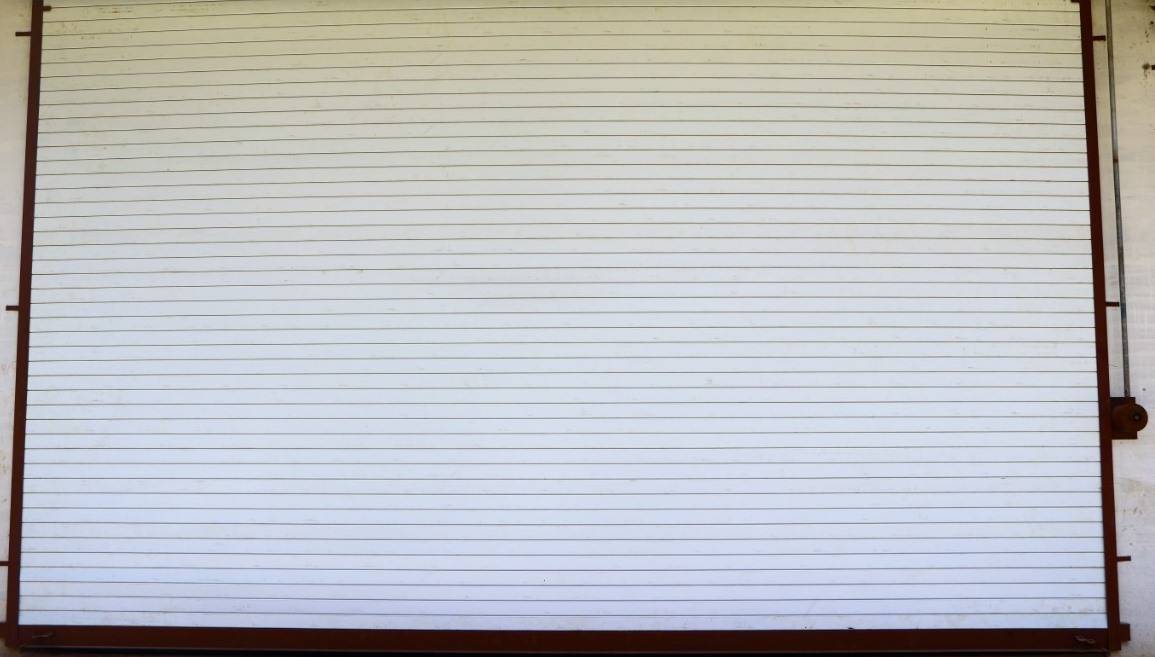

We manufacture curved slats and flat slats. According to the slats used for making the curtain for rolling shutter they are named as curved (corrugated) rolling shutter and flat rolling shutter.

Curved rolling shutters are made using slats (laths) which are curved with curls at both edges for interlocking and a deep corrugation at the center. The curved slats provide sufficient resistance against manual pressure and normal wind pressure.

Flat rolling shutters are made using slats which are flat in the center and have curls at both the edges. Flat rolling shutter gives a simple and classy view when they are closed. Each lath is interlocked to form a curtain.

Galvanized rolling shutter

Galvanization is the process of applying a protective zinc coating to iron, to prevent rusting. GI rolling shutters is a long lasting investment for residential or commercial use.

Gear operated rolling shutter

This type of operation is preferred commonly for commercial use. when the width and height of the rolling shutter are more. For opening and closing the Rolling shutter a crank handle is used to rotate the gear enabling the rolling mechanism.

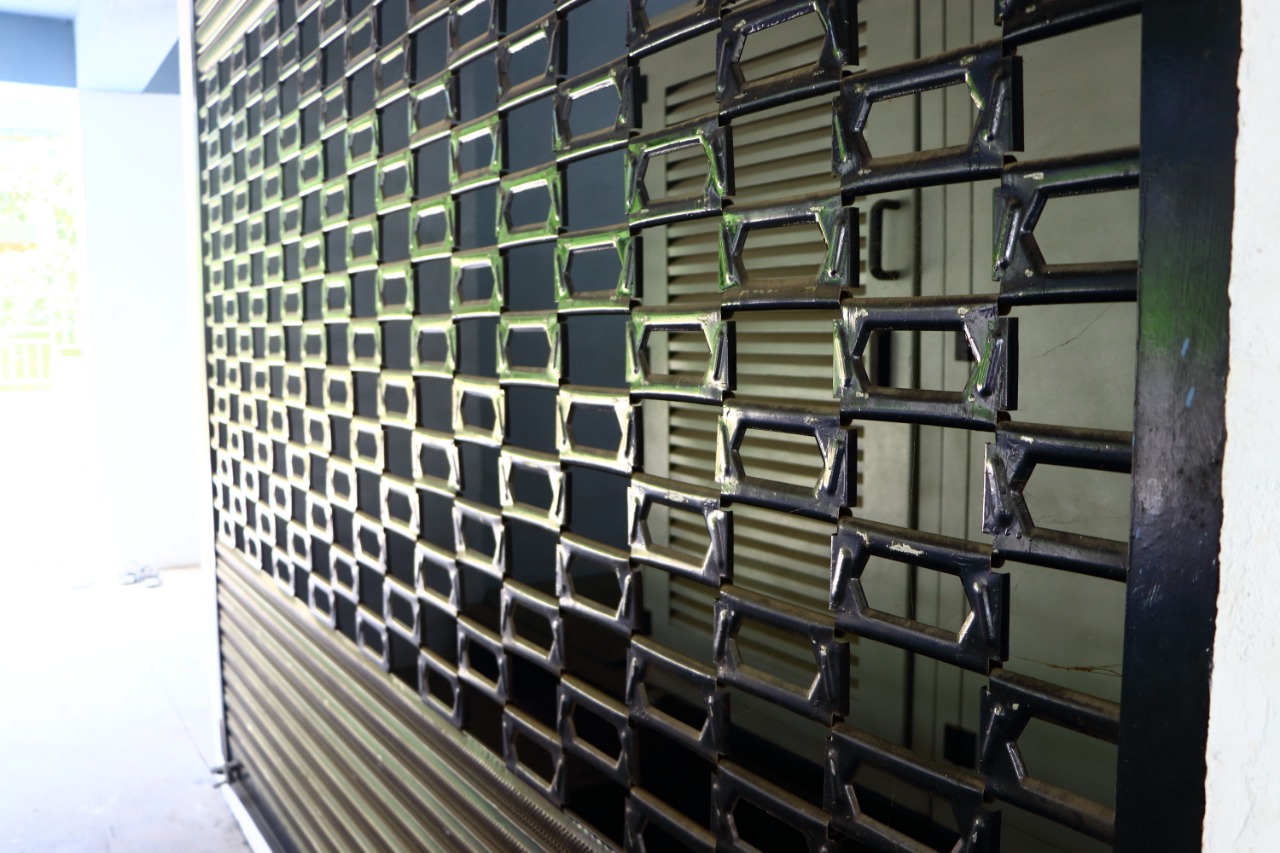

GRILL shutter

The grill type rolling shutter is used to give maximum light, see-through and ventilation, hence ideal or places like generator rooms. They are available in different designs and styles.

MOTORIZED rolling shutter

By using a motor for enabling the rolling mechanism, smooth operation of rolling shutter can be achieved. Push-button is used for opening and closing.

PERFORATED ROLLING shutter

They are made by using slats having perforations for seeing through them, which makes them a good choice for open spaces in homes, shop-fronts and by giving a combination of these perforated slats with powder coated slats it gives a different look when used for garages.

POWDER COATED ROLLING shutter

Powder coating is usually used to create a hard finish that is tougher than conventional paint. It helps in protecting the metal onto which it is done against corrosion.

FOR ESTIMATION / SERVICES